Abstract

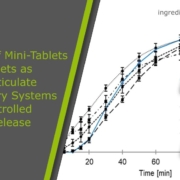

Mini-tablets made into hard capsules or administered using special dosing units, as well as pellets in hard capsules or compressed into tablets, offer the advantages of multiparticulate drug delivery systems and are suitable for controlled drug release using polymer coatings. Four different kinds of solid drug preparations were manufactured and investigated concerning drug release. Inert pellets were coated with the model drug sodium benzoate and, in a second step, with the insoluble polymer ethylcellulose. The coated pellets were compressed into mini-tablets and into normal tablets. Another kind of mini-tablet was compressed from a sodium benzoate compression mixture and finally coated with ethylcellulose. The coating of the tablets was performed using fluidized bed technology. The sodium benzoate release plots of the coated pellets show a lag time and retarded release according first-order kinetics. The mini-tablets and normal tablets compressed from pellets release sodium benzoate according to first-order kinetics as well, but without the lag time due to distinct ethylcellulose layer destruction during tableting. The release is retarded with increasing ethylcellulose layer thickness on directly compressed mini-tablets. The different formulations of coated pellets, mini-tablets, and normal tablets offer a broad choice for variable drug release kinetics depending on the biopharmaceutical and pharmacological requirements.

Conclusion

Drug- and polymer-coated pellets may be compressed into mini-tablets as well as into normal tablets. Pellets and mini-tablets compressed into tablets as a multiparticulate drug delivery system offer the advantage of being widely spread in the small intestine for improved drug absorption and increased bioavailability compared to normal tablets. With both tablet types (normal and mini), the sodium benzoate release is delayed depending on the thickness and properties of the ethylcellulose film on the pellets.

Ethylcellulose-coated mini-tablets obtained through the direct compression of sodium benzoate and excipients are an alternative method for multiparticulate drug delivery system preparation. The product is characterized by a slow release rate depending on the ethylcellulose film thickness that may be suitable when prolonged release is required. The variation in release is increased compared to pellets and normal multiple-unit tablets with pellets. Sodium benzoate layering on pellets in the fluidized bed and the subsequent tableting process are feasible for both mini-tablets and normal tablets, representing an interesting option when a variation in the final pharmaceutical form is required for marketing/patenting reasons.

Authors

F. Priese, D. Wiegel, C. Funaro, G. Mondelli, and B. Wolf

Coatings 2023, 13(11), 1891; https://doi.org/10.3390/coatings13111891

Read more

Read more about how CELLETS 200 are employed in mini-tablets and pellets as multiparticulate drug delivery systems by F. Priese et al. here.