Are you having questions on pharmaceutical MCC pellets? Just contact us, we can answer.

What are pellets in pharmaceutical formulations made of?

Pellets in pharmaceutical formulations are generally made of

- Microcrystalline Cellulose

- Isomalt

- Sugar

- Lactose-Starch

- Lactose-Cellulose

- Dibasic Calcium Phosphate

- Carnauba wax

- Silica

- Polyols

- Tartaric acid (functional)

pellets in pharmaceutical formulations Q&A

What is pellet technology?

Pellet technology describes how starter pellets are processed as excipients in pharmaceutical formulations. They are coated and layered with APIs and excipients. In the following, defined drug release profiles or taste-masking are realized.

See: pellet technologies.

What are functional pellets?

Functional pellets serve an additional value or functionality for drug deliveries in oral drug formulations (pellet technology). Typically, tartaric acid pellets servce an acidic local environment improving the dissolution of weakly basic APIs.

Functional pellets – Q&A

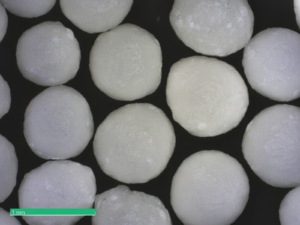

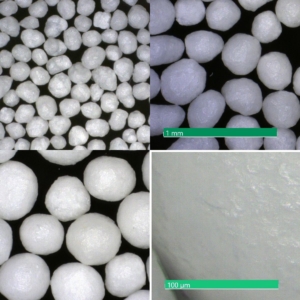

What are neutral microcrystalline cellulose pellets?

In the first place, neutral microcrystalline cellulose pellets show no or negligible influence on the drug formulation. Also the dissolution characteristics are not changed. Consequently, they interact as pure drug carrier systems. Bioavailability is not affected.

See: Cellets

Cellets 700, Neutral microcrystalline cellulose pellets – Q&A

Are you having questions on pharmaceutical MCC pellets? Just contact us, we can answer.

What are pellet specifications?

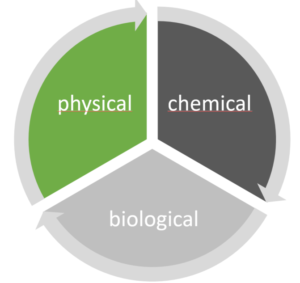

Pellet specifications arise from the regulations for pharmaceutical excipients. Cellets, which are microcrystalline pellets, are excipients. There are physical, chemical and biological specifications:

- Physical specifications: particle size distribution, loss on drying, bulk density, sphericity degree, friability, swelling index.

- Chemical specifications: identification infrared absorption, identification zinc chloride test, degree of polymerization, pH value, conductivity, ether soluble substances, water soluble substances, heavy metals, sulfated ash.

- Biological specifications: total aerobic microbial count, fungi / moulds and yeasts, E.coli Ps aergin St. Aureus, Samonella species.

Pellet specifications: parameters

Pellet specifications are given by regional pharmacopoeia which serves and defines common quality standards throughout the pharmaceutical industry in different regions world-wide. The most important pharmacopoeia are:

- Eur Ph: Pharmacopoeia Europaea, pharmaceutical standards in Europe,

- JP: Japanese Pharmacopoeia, pharmaceutical standards in Japan and

- JPE: Japanese Pharmaceutical Excipients, pharmaceutical standards for excipients in Japan,

- USP-NF: United States Pharmacopeia (USP) and the National Formulary (NF), pharmaceutical standards in USA

There are several minor national standards which needs to be considered for the respective markets.

Cellets are specified by the strictest pharmaceutical standard (Eur Ph, JP/JPE, USP/NF) for each specification. See: Cellets product information

Where to buy pellets for pharmaceutical use?

You can buy pellets for pharmaceutical use in many countries world-wide. Pharmaceutical pellets by Ingredientpharm follow specifications by Eur.Ph., JP/JPE, USP/NF, an import into your country is generally not a big issue. Please, ask us for help.

We offer highest quality through our distribution channels. Experts from our distributors will advise and find with you the best solution. Depending on your goals, API and formulation, there are several pellet materials and sizes available.

Buy pellets for pharmaceutical use here: web-shop.

How to order pharmaceutical pellets?

You can order pharmaceutical pellets in many countries world-wide. Pharmaceutical pellets by Ingredientpharm follow specifications by Eur.Ph., JP/JPE, USP/NF, an import into your country is generally not a big issue. We are happy to assist you with any question.

We offer highest quality through our distribution channels. Our distributors will advise and find with you the best solution. Depending on your goals, API and formulation, there are several pellet materials and sizes available.

Order pellets for pharmaceutical use here: web-shop.

order pharmaceutical pellets

What are formulations with starter pellets

Frequently, formulations with starter pellets are based on multiparticulates. Formulations for immediate release and extended release oral dosage forms are more and more often built on starter pellets. Experts such as Glatt Pharmaceutical Services can assist you or take over control of the entire drug processing. The way, how formulations with starter pellets are processed and manufactured is called pellet technologies. A large variation of desired functionalities of the final drug can be easily implemented. Customer compliance (e.g. taste-masking) and marketing targets (e.g. designed taste & color) can be realized.

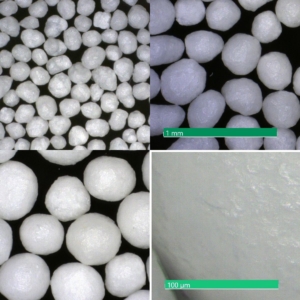

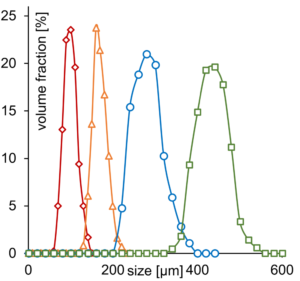

Which is the size of pharmaceutical pellets?

The size of pharmaceutical pellets is between 100 µm and 1400 µm. For the sake of high monodispersity, pharmaceutical pellets are ordered in different size classes. For example, microcrystalline cellulose pellets (Cellets) are available in standard classes:

- Type of MCC pellet

- Cellets 100

- Cellets 200

- Cellets 350

- Cellets 500

- Cellets 700

- Cellets 1000

- size of pellets (*)

- 100-200 µm

- 200-355 µm

- 350-500 µm

- 500-710 µm

- 700-1000 µm

- 1000-1400 µm

(*) Test method: Cellets Standard. Particle size distribution ≥ 85 %. Overview. / technical specifications.

Advantage of small pellet sizes:

- large surface-to-volume ratio

- small elementary particles in formulations

- easy swallowing and high customer compliance

- application: mini-tablets, capsules, tables

Advantage of large pellet sizes:

- small surface-to-volume ratio

- large elementary particles in formulations

- easy coating and layering of small excipient or API fractions

- application: tables, sachet, stick packs

Special sizes are avialable on request. See for more information: Cellets product information. Size of functional tartaric acid pellets (TAP): See: TAP product information.

A converter which relates pellet sizes and mesh sizes of sieves is a meaningful tool.

What are the advantages of pellets in oral dosage forms?

The advantages of pellets in oral dosage forms compared to monolithic dosage forms are:

- low variability of gastric emptying

- lower dependency on nutrition state

- low risk of localized high drug concentrations in the GI

- reduced risk of sudden dose dumping

- lower intra- and inter-individual variability

- high control on time and place of drug delivery

More details on: cellets.com

advantages of pellets in oral dosages

What is a drug carrier system?

A drug carrier system, such as starter pellets, allows coating and layering with APIs and excipients, resulting in better formulations of pharmaceutical products. Drug carrier systems can improve drug availabiliy, assist formulations, or realize higher safety for the API:

- Multiple small discrete units are coated with the API

- Unit sizes are between 100 and 1400 µm

- Variability in systemic absorption

- Reduced risk, for example dose dumping

- Better compliance by taste masking, palatability

- Easy to swallow (geriatric medicine)

There is a large scientific community and publications on research on microcrystalline cellulose pellets serving as drug carrier.

More general information about drug carrier system on wikipedia.

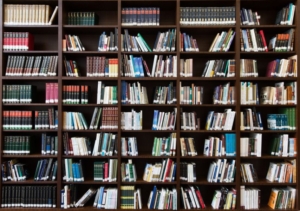

Is scientific data for MCC pellets available?

Scientific data for MCC pellets is available. Far more than 100 publications and papers are presented here. Most of the world-wide studies are performed with Cellets which are microcrystalline cellulose pellets.

See the publication list.

scientific data for MCC pellets

Are case studies with pellets availabe?

Case studies with pellets are available. Many case studies point onto pellet technologies in oral drug formulations. Main issues ot case studies are:

- taste-masking of bitter API

- investigations on transport & drug carrier system

- process properties, such as physical and chemical parameters, alias specifications

List of case studies on different pellet types:

- case studies here for microcrystalline cellulose (MCC) pellets

- case studies for tartaric acid pellets

Please, contact us for more details. We welcome scientific communications. So you like to start research with pharmaceutical starter pellets? Ingredientpharm has chances to assist you: info@ingredientpharm.com.

exemplarily: case studies with pellets

Who can assist pellet formulations for oral dosage forms?

Experts such as Glatt Pharmaceutical Services can assist pellet formulations or take over control of the entire drug processing:

- formulation development

- pre-clinical and clinical phase

- Analytics

- clinical test samples

- commercial manufacturing

- technical infrastructure

- logistics & warehouse

Contact to experts: pharmaceuticalservices@glatt.com

Experts assist pellet formulations for oral dosage forms

Is there an impact of the particle size on powder behavior in a Wurster fluid-bed process?

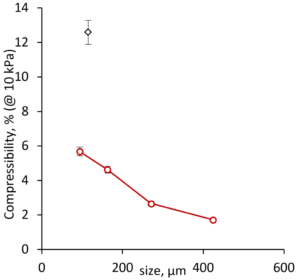

Yes, the flow of MCC pellets (Cellets) through a Wurster fluid-bed coater shows better performance as the Cellets’ particle size increases. The flow behavior is outperforming standard MCC powder. This was investigated by Mohylyuk et al. (2019), doi: 10.1016/j.jddst.2019.101320. Find more information: Is there an impact of the particle size on powder behavior in a Wurster fluid-bed process?

Impact of the particle size on powder behavior in a Wurster fluid-bed process: Compressibility at 10 kPa normal stress on Cellets with varying particle size (D50) and Avicel® PH-102.

Are you having more questions on pharmaceutical MCC pellets? Just contact us, we can answer.