Hot-melt coating materials improve efficiency and product quality in pharmaceutical and industrial manufacturing. They melt when heated and solidify quickly, forming strong, uniform coatings on various surfaces. As a result, manufacturers reduce production time, lower costs, and avoid using solvents. Furthermore, understanding wetting behavior and delamination is critical to optimize coating performance. For example, CELLETS® 1000 microcrystalline cellulose pellets serve as excellent starter cores, promoting uniform wetting and consistent coating thickness. Consequently, hot-melt coating materials have become a reliable solution for modern manufacturing needs.

Enhancing pharmaceutical and industrial applications by hot-melt coating materials

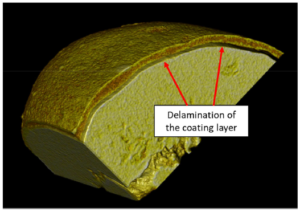

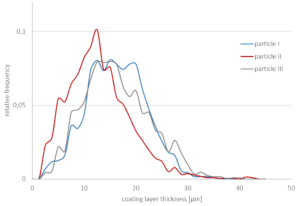

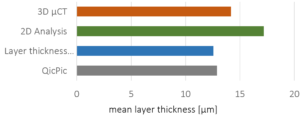

In the study titled Delamination and Wetting Behavior of Natural Hot-Melt Coating Materials, published in Powder Technology [1], the authors investigated the delamination and wetting behaviors of various natural materials. The research aimed to understand how these materials interact with substrates during the coating process, which is crucial for applications in the pharmaceutical industry. The study utilized laboratory coating experiments and micro-computed tomographic measurements to assess delamination frequency, and a drop shape analyzer to evaluate wetting behavior. Interestingly, the study found no correlation between delamination and wetting behavior, suggesting that other factors may influence delamination in hot-melt coatings.

Among the materials tested, CELLETS® 1000, a type of microcrystalline cellulose (MCC) pellet with a size range between 1000 and 1400 µm, was highlighted for its suitability in hot-melt coating applications. These spherical pellets are known for their chemical inertness, low friability, high sphericity, and smooth surface, making them ideal as starter cores for multiparticulate drug delivery systems. In the context of the study, CELLETS® 1000 demonstrated excellent wetting properties with contact angles ranging from 10° to 18°, which is favorable for uniform coating. However, the study did not find a direct correlation between wetting behavior and delamination, indicating that other factors may play a more significant role in delamination during hot-melt coating processes. Researchers assume that delamination may have resulted from the different thermal expansion coefficients of the carrier particle and the coating material [2]. A change in temperature may have led to thermal stresses and may have promoted spalling or delamination. Subsequent swelling of a hygroscopic carrier material due to moisture could also lead to structural

changes in the coating structure and might cause delamination.

Use of CELLETS® in hot-melt coating processes

The use of CELLETS® in hot-melt coating processes offers several advantages. Their uniform size distribution and smooth surface contribute to consistent coating thickness and quality. Additionally, the chemical inertness of CELLETS® ensures compatibility with a wide range of coating materials, reducing the risk of undesirable interactions. These characteristics make CELLETS® a reliable choice for developing controlled-release formulations and enteric coatings in pharmaceutical applications.

In summary, the study underscores the importance of understanding the delamination and wetting behaviors of natural hot-melt coating materials. While CELLETS® 1000 exhibited favorable wetting properties, the lack of correlation between wetting behavior and delamination suggests that other factors should be considered when selecting materials for hot-melt coating processes. Further research is needed to identify these factors and optimize coating processes for improved product performance.

References

[1] B.M. Wörthmann et al., Powder Technology (404) 2022, 117443; doi: 10.1016/j.powtec.2022.117443.

[2] S. Ebnesajjad, A.H. Landrock, Introduction and adhesion theories, Adhesives Technology, Handbook, 38, Elsevier 2015, pp. 1–18; doi: 10.1016/B978-0-323-35595-7.00001-2.

Understanding Hot-Melt Coating Materials

Hot-melt coating materials are thermoplastic substances that bond effectively to substrates when melted. Their melting point, adhesion properties, and chemical compatibility directly influence coating uniformity and durability. Therefore, selecting the correct material is crucial for minimizing delamination and ensuring product quality. Additionally, their solvent-free nature makes them environmentally friendly and cost-efficient.

Optimizing Coating with CELLETS®

CELLETS® offer significant advantages as starter cores in hot-melt coating processes. Their spherical shape and smooth surface promote uniform wetting and consistent coating thickness. Furthermore, their chemical inertness ensures compatibility with diverse coating materials, reducing the risk of unwanted interactions. Consequently, these MCC spheres support reliable and high-quality coating outcomes in both pharmaceutical and industrial applications.