Abstract on Continuous Manufacturing

Conclusions

Authors:

Aytug Kara, Dinesh Kumar, Anne Marie Healy, Aikaterini Lalatsa, and Dolores R. Serrano.

Read more

Abstract on Tamoxifen

Tamoxifen is widely used in transgenic research in mice to induce Cre recombinase activity and achieve conditional gene knockouts [1]. However administrating tamoxifen to mice is challenging The commonly used dosing methods are oral gavage or intraperitoneal injection [2] which require specialist staff training and can cause pain, distress and adverse effects to the animal. Tamoxifen containing rodent chow is commercially available however, the poor palatability of the diet leads to reduced food intake and weight loss of the mice. The addition of sweeteners improves palatability, but this can affect the metabolic balance of the mice.

In this application a study is described in which a palatable tamoxifen containing rodent chow is developed by mixing taste masking coated micropellets with powdered rodent food. This attempt shell improve:

- Reduction of potential welfare concerns,

- Reduction of dose variability,

and induce

- a more consistent recombinase activity,

- a decrease in the variability of phenotyping data from these experiments,

- a reduction in the number of animals used

Methods

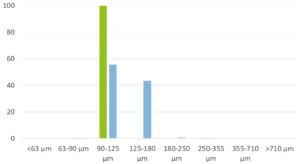

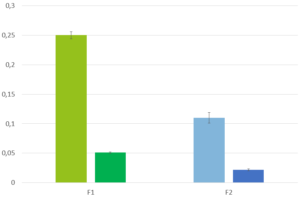

The API was spray layered onto microcrystalline cellulose substrates CELLETS® 100 and subsequently coated using Surelease®, both as aqueous formulations in a bench top fluidized bed coater (Mini Glatt®). Two taste masking coated tamoxifen citrate micropellet formulations were prepared and analyzed. One formulation has a coating levels of 5 % (F1) and the second formulation contains mannitol in the drug layer with a coating level of 10 % (F2). Sieve analysis of taste masking coated micropellets (Figure 2) shows that both formulations achieved yields of at least 99 % (proportion of pellets with size < 250 µm), see Fig. 1.

Figure 1: Tamoxifen sieve analysis. Graphs: F1 (light green); F2 (light blue).

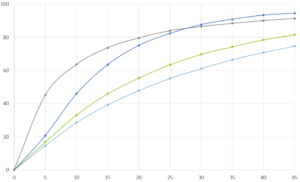

In USP II dissolution test the uncoated tamoxifen citrate (micronized and un-micronized particles) showed a fast dissolution at >80 % release within 45 minutes (Figure 3). The micronized particles dissolved slower than the un-micronized due to particle agglomeration during dissolution.

Drug release slowed down after applying the taste masking coating; with decreasing pore former concentration or increasing coating thickness, the drug release rate decreases. After 45 min, both formulations F1 and F2 showed >75 % drug release, successful as immediate release formulations (Fig. 2).

Figure 2: Drug release of Tamoxifen Citrate in USP II test. Graphs: F1 with coating Level 5 % and polymer ratio 75:25 (light green); F2 Mannitol with coating level 10 % polymer ratio 85:15 (light blue); Tamoxifen Citrate micronized (blue); Tamoxifen Citrate un-micronized (grey).

Taste masking effectiveness of Tamoxifen micropellets

The in vitro tests for evaluating the taste masking effectiveness of the formulations showed that after 30s, micropellets with both coating formulations are effective in providing a taste masking barrier with a tamoxifen citrate release of less than 0.5% (Fig. 3).

Figure 3: Inverted Vial test for taste masking effect evaluation. Graphs: F1 (green), F2 (blue) with % Release after 30s (light color) and Concentration (mg/ml) after 30s (dark color).

Summary

Taste masking of coated tamoxifen citrate micropellets were successfully manufactured in a fluidized bed applying the MicroCoat™ technology with > 99% yield and particle size < 250 µm. The coating provided effective protection to prevent tamoxifen citrate release in the mouth but immediate drug release in the stomach pH conditions of the mice. Additionally, the small particle size of the coated micropellets ensured effective mixing with the powder rodent feed with excellent recovery and uniformity. The product is flexible in dose adjustment and improves API handling safety in animal units, offering an innovative approach of doing tamoxifen to mice for Cre recombination research via voluntary food intake. The method has the potential to reduce suffering

and improve welfare of the mice, promoting 3Rs (replacement, reduction and refinement) in animal research.

Taste masked coated micropellets

Acknowledgement

The project is funded by the United Kingdom National Centre for the Replacement, Refinement and Reduction of Animals in Research (the NC3Rs) through the CRACK IT challenge Tat Fit project number NC/C020S02/1).

Dr. Fang Liu and her team are gratefully acknowledged for serving content for this note.

Fluid Pharma Ltd

Contact: Dr. Fang LIU

College Lane, Hatfield, AL10 9AB, UK

Tel: +44 1707 28 4273

+44 796 3230 628

www.fluidpharma.com

Glatt

Glatt