Abstract on Continuous Manufacturing

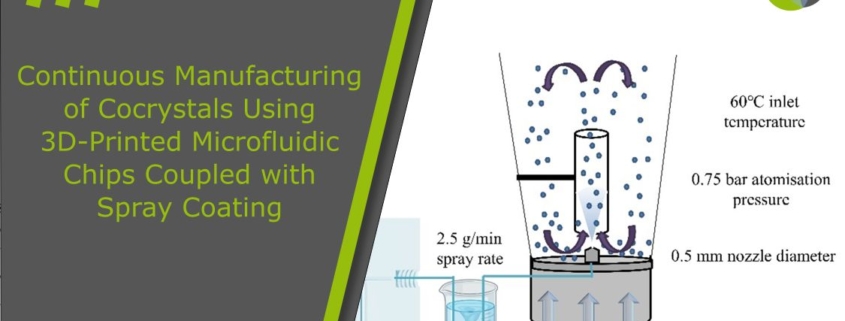

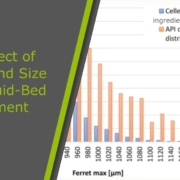

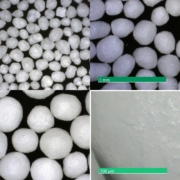

Using cocrystals has emerged as a promising strategy to improve the physicochemical properties of active pharmaceutical ingredients (APIs) by forming a new crystalline phase from two or more components. Particle size and morphology control are key quality attributes for cocrystal medicinal products. The needle-shaped morphology is often considered high-risk and complex in the manufacture of solid dosage forms. Cocrystal particle engineering requires advanced methodologies to ensure high-purity cocrystals with improved solubility and bioavailability and with optimal crystal habit for industrial manufacturing. In this study, 3D-printed microfluidic chips were used to control the cocrystal habit and polymorphism of the sulfadimidine (SDM): 4-aminosalicylic acid (4ASA) cocrystal. The addition of PVP in the aqueous phase during mixing resulted in a high-purity cocrystal (with no traces of the individual components), while it also inhibited the growth of needle-shaped crystals. When mixtures were prepared at the macroscale, PVP was not able to control the crystal habit and impurities of individual mixture components remained, indicating that the microfluidic device allowed for a more homogenous and rapid mixing process controlled by the flow rate and the high surface-to-volume ratios of the microchannels. Continuous manufacturing of SDM:4ASA cocrystals coated on beads was successfully implemented when the microfluidic chip was connected in line to a fluidized bed, allowing cocrystal formulation generation by mixing, coating, and drying in a single step.

Conclusions

SDM:4ASA cocrystal particle engineering has been successfully achieved using 3D-printed microfluidic chips. The addition of PVP in the aqueous phase during mixing has allowed the inhibition of needle-shaped crystals and the generation instead of spherical crystal habits with higher purity compared to conventional mixing. A successful continuous manufacturing method for the fabrication of cocrystal-coated particles has been demonstrated by the combination of microfluidic chips with a fluidized bed, allowing the process intensification of mixing and drying in one step.

Authors:

Aytug Kara, Dinesh Kumar, Anne Marie Healy, Aikaterini Lalatsa, and Dolores R. Serrano.

Read more

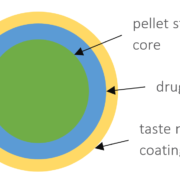

Read more on continuous manufacturing of cocrystals by Kara et al. here and find out the functionality of CELLETS® 500 (pellets made of microcrystalline cellulose, size: 500-710 µm).

Ingredientpharm

Ingredientpharm